Mandatory Boiler Inspections

Make sure the pressure systems are operating properly with Mandatory

Boiler Inspections

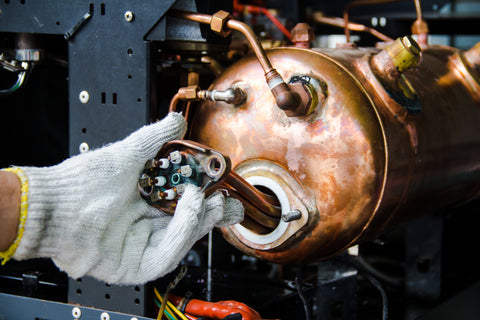

If your coffee machine is equipped with a boiler, it will need to undergo a PSSR inspection. The Pressure Systems Safety Regulations were established in 2000.

These regulations mandate that pressurised steam systems (ranging from steam-generating coffee machines to large commercial boilers) be inspected annually to demonstrate compliance and ensure the safety of the equipment.

We can help you fulfil this obligation.

Whether you need an engineer, inspector, or both, this is just one of the many services we provide.

Why Boiler Inspections are crucial for safety

Assists in Pinpointing Potential Issues

Prevent problems such as leaks, cracks, corrosion, or any other damages to critical components that may compromise the safety and performance of the equipment.

Ensures Regulatory Compliance

The Pressure Systems Safety Regulations 2000 require pressure systems to be inspected according to a certified Written Scheme of Examination.

Extend Machine Lifespan

By having a certified technician carry out regular inspections, you can identify minor issues before they lead to significant damage.

The statutory examination is designed to ensure that the pressure system within your commercial machine is safe for continued operation and therefore helps to protect every person who may come into contact with or be in the vicinity of that machine.

The procedure for system examination includes:

1. Safely shutting down the coffee machine completely.

2. Inspecting and testing the steam pressure boiler, associated pressure system, and pipework in accordance with a Written Scheme of Examination.

3. Reassembling the coffee machine and replacing the heating element gasket.

4. Conducting a hot test to ensure that the protective/control devices are functioning as recommended by the manufacturer.

5. Submitting the findings to the support team for a detailed examination report and a Written Scheme of Examination.

If the machine fails, a second visit is required, and the equipment must remain at zero pressure until full maintenance is carried out and a Written Scheme of Examination is put in place.

An annual planned coffee machine maintenance is recommended in 6 month, annual or per cups intervals.

When it comes to coffee machine maintenance service pricing, there are several common components to consider:

- Inspection and cleaning

- Replacement of worn or damaged parts

- Calibration and adjustment

- Preventative maintenance

The cost of coffee machine maintenance service depends on various factors including the complexity of the machine, the extent of repairs or maintenance required, and the location of the service.

To ensure informed decision-making about pricing, it is important to obtain a detailed quote.

Tailored preventative maintenance plans for the specific needs of your business.

Tell Us Your Requirements

Discover More About PSSR and Mandatory Inspections for Commercial Espresso Machines

Legal Requirement

To ensure compliance with the Pressure Systems Safety Regulations 2000 (PSSR 2000), if you possess a commercial coffee machine equipped with a steam boiler, it is mandatory to follow a certified Written Scheme of Examination for inspecting pressure systems containing 'relevant fluids,' such as steam.

Risk of Noncompliance

Failure to have the mandatory boiler inspection services carried out for an espresso machine incorporating a steam boiler following a Written Scheme of Examination will result in non-compliance with PSSR 2000, which can lead to criminal charges.